Oil-free air compressors offer various benefits, including affordability, low maintenance and environmental friendliness. They’re an excellent choice for businesses or individuals who use or are looking to use air compressors and want a practical, convenient option. Read on to learn about their many applications, as well as the advantages they provide over traditional oil-injected compressors.

Oil vs. Oil-Free Air Compressors

When picking a compressor for your application, you’ll need to choose between two basic options: oil-injected and oil-free. If you’re new to the world of air compressors, you may be unfamiliar with the differences.

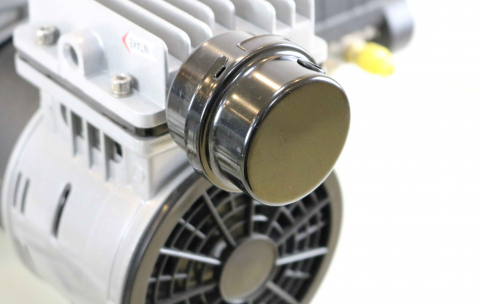

The fundamental difference between the two lies in how the pistons — which draw in air and compress it in a storage tank — are lubricated. Oil-injected compressors, as the name implies, use oil to lubricate the pistons. In oil-free compressors, however, the cylinders are instead coated with Teflon and therefore do not need to be lubricated. These air compressors do not need oil, which eliminates the additional time and money you’d otherwise spend on procuring and applying lubrication to your machines.

Benefits of Oil-Free Compressed Air

Oil-free compressors offer several advantages over their oil-injected counterparts, including:

• Less maintenance: Traditional oil air compressor maintenance is somewhat involved. These machines require routine oil changes, which means you also have to dispose of this oil. This action costs more money and time. You also have to remove oil aerosols, for which you’ll need filtration and oil and air separator elements. With oil-free air compressors, you don’t have to do any of these tedious chores — although draining the tank completely after every use is recommended to extend the compressor’s lifespan.

• Lower cost: Oil-free compressors are also a great way to save money. They generally cost less to buy, and they also tend to last a long time, due to their relatively few components. Some models also come with regulators that allow you to use energy only when it’s needed, which helps lower fuel costs.

• Environmentally friendly: The compressor’s absence of oil is eco-friendly because the machine doesn’t release pollutants into the atmosphere. These substances can harm both the environment and your workers.

• Diminished risk of contamination: Oil contamination can lower or compromise the quality of your products, which in turn could harm your brand’s reputation — or even worse, your customers’ health. Oil-free compressors are often required in fields like food and medicine, where oil-free, clean air is essential.

• Multiple uses: Unlike oil-injected compressors, oil-free types can operate when placed in various orientations. Due to their lighter weight and smaller size, they can be easily transported and moved vertically or horizontally, depending on the task. And since they’re oil-free, you won’t have to worry about oil leaking when the compressor is tilted in different directions.

• Faster start: Oil-injected compressors require more amps to start. This means that if you were hoping to use one in a cold environment, such as a garage on a winter day, starting it could take a while. This issue is due to oil’s viscous consistency, which makes it more difficult to move when cold. If you have an oil-free compressor, though, you can start it much faster, regardless of the temperature.

In short, there are numerous advantages to using oil-free compressors. Whichever application you’re using it for, an oil-free compressor can help protect the environment and lower your operational costs. These reasons alone may be enough motivation to choose one of these machines over a traditional oil-based model.

=====

Contact us now or visit All Air Compressors' website for more information about our services!

Source: quincycompressor