Why settle for the status quo when the future of building materials is already here, transforming industries with its resilience and versatility? The hero of this narrative is none other than industrial plastic. It's a once underestimated material that's now pivotal in driving innovation across the globe.

From towering skyscrapers to intricate medical devices, industrial plastic is the unsung protagonist. It offers solutions that traditional materials cannot match.

This article is a window into a world where efficiency, sustainability, and technological advancement converge through the use of industrial plastic. By embracing the myriad of benefits it presents, businesses and industries can revolutionize their operations, reduce costs, and step into a greener, more adaptable future. Read on to discover how industrial plastic can redefine your commercial strategy and lead you toward a more innovative, cost-effective, and sustainable path.

1. Cost-Effectiveness

When it comes to choosing materials for any project, the bottom line matters. That's where industrial plastic shines. It's not just affordable to buy; it costs less over time too.

Think about it: plastic doesn't rust, doesn't need painting, and can withstand a lot without breaking down. This means you're not spending money on upkeep like you would with metal or wood.

Plus, it's lighter, slashing shipping costs. Imagine sending a truckload of material across the country. If it's plastic, you're paying for a lot less fuel.

This makes plastic a smart pick for your wallet from start to finish. It's hard to ignore these benefits, especially when you're saving money in the long run.

2. Durability and Longevity of Industrial Plastic

Industrial plastic isn't a one-hit wonder. It's made to last. Unlike metals that can corrode or wood that might rot, plastic stands strong against the elements.

It laughs in the face of corrosion, doesn't care about moisture, and UV light? No big deal.

Some types of plastic, like polyethylene and polycarbonate, are especially tough. They can handle heavy use and harsh conditions without showing their age. This means whatever you build with plastic materials, whether it's outdoor furniture or industrial tanks, you can count on it to last years, maybe even decades.

3. Lightweight Nature

One of the biggest perks of industrial plastic is how light it is. This isn't just about making things easier to carry around, though it does that too. Lighter materials mean lower shipping costs, simpler handling, and often, easier installation.

In industries like automotive or aerospace, where every ounce matters, using plastic can make things significantly lighter. This leads to better fuel efficiency for cars and planes, which is good for both the planet and the pocketbook. It's a win-win that's hard to ignore.

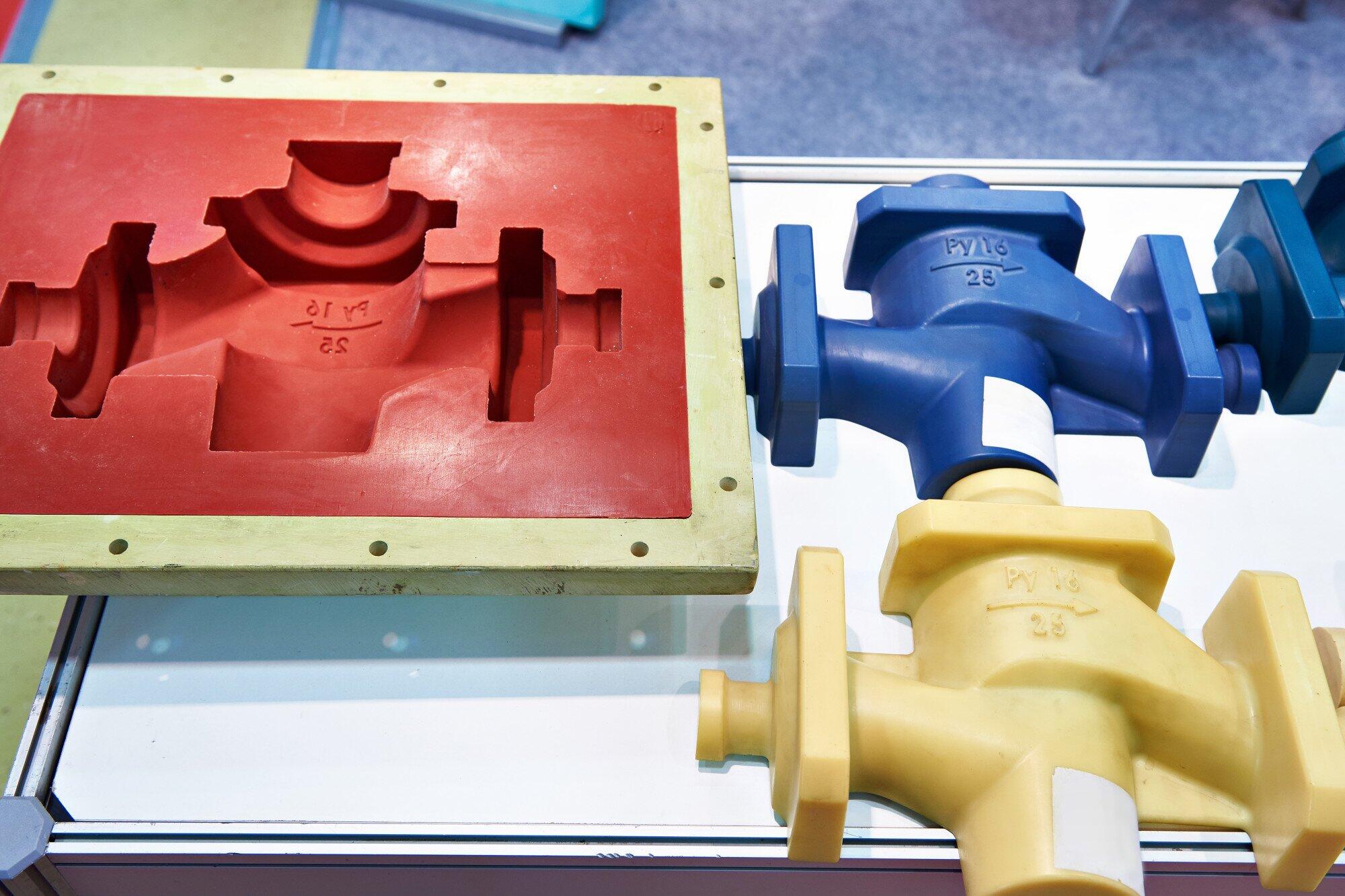

4. Versatility

Industrial plastic is like a chameleon. It can fit into any role, in any industry, with ease. From clear, durable panels for safety shields to flexible tubing for medical devices, plastic's range is vast.

This adaptability is thanks to the ability to tweak its properties. Need something that can withstand high temperatures? There's a plastic for that.

Looking for custom plastic parts in specific colors or textures? No problem.

This versatility makes plastic a go-to material for innovators and problem-solvers in fields from construction to healthcare.

5. Resistance to Chemicals

In environments where chemicals are part of the daily grind, industrial plastic is invaluable. Its resistance to a wide array of substances means it can safely store and transport everything from water to hazardous chemicals without degrading.

This isn't just a minor benefit. It's a game-changer in industries like chemical manufacturing, where safety and integrity of containment are paramount.

Plastic's ability to shrug off chemical attacks makes it an essential ally in keeping operations running smoothly and safely.

6. Easy to Fabricate and Install

Plastic fabrication stands out for its simplicity and efficiency. Unlike materials that require complex processes or specialized equipment, plastic is straightforward to work with.

Cutting, welding, and molding plastic into the desired shapes and sizes can be done quickly, which speeds up the entire construction or manufacturing process. This ease of fabrication not only saves time but also significantly reduces labor costs and the need for expensive tools.

Whether it's for creating custom plastic components or large-scale industrial parts, the process is streamlined. This makes projects more manageable and cost-effective.

7. Energy Efficiency

When we talk about energy efficiency, industrial plastic is a star player. The production and processing of plastic materials generally use less energy compared to manufacturing metal or glass. This lower energy requirement means fewer carbon emissions which contributes to a greener manufacturing process.

Moreover, plastic's insulation properties are superior, helping to conserve energy in buildings and products. For example, plastic window frames can better retain heat in a home than their aluminum counterparts. This leads to significant savings on heating bills.

This energy-saving aspect of plastic makes it an environmentally and economically smart choice.

8. Environmental Impact

The environmental impact of plastic manufacturing has been a hot topic, but the narrative is changing thanks to advancements in technology and sustainability practices. Today, more companies are adopting eco-friendly methods in plastic manufacturing. These can significantly reduce waste and energy consumption.

Additionally, the development of recyclable and biodegradable plastics is on the rise. This shows a commitment to reducing the ecological footprint.

These sustainable options offer a way to enjoy the benefits of plastic while ensuring the health of our planet. By focusing on recycling and responsible production practices, the industry is working towards a more sustainable future. This widespread adoption proves that plastic can be part of an eco-friendly solution.

Beyond the Material World

Embracing industrial plastic isn't just a choice. It's a strategic decision for a sustainable, efficient, and innovative future.

Throughout this article, we've unveiled the unparalleled benefits of industrial plastic, from its cost-effectiveness and durability to its environmental advantages. These qualities make industrial plastic a cornerstone for industries looking to thrive in modern challenges.

Dive deeper into the world of industrial plastics and discover more about how this material is shaping the future of industries. Explore our blog for more insights and innovations that can help you stay ahead in your field.